How To Select Steel Barrier Bases

Last updated Monday, May 30th, 2022

Introduction

The most vulnerable part of a steel barricade is its bases. The wear and tear caused by the use and movement of a steel barrier will most often become evident in damage to the bases.

To minimize the risk of having any of your barriers “out of commission” due to base damage, purchase barriers with bolt-on replaceable bases, rather than welded-on bases. Barriers that feature bolt-on replaceable bases are much more cost-effective. A barrier with a damaged base won’t sit idle for long – it is very easy and inexpensive to replace a base, as opposed to purchasing an entire new barrier.

There are four main types of interchangeable bases for steel barricades. Each offers advantages for specific applications.

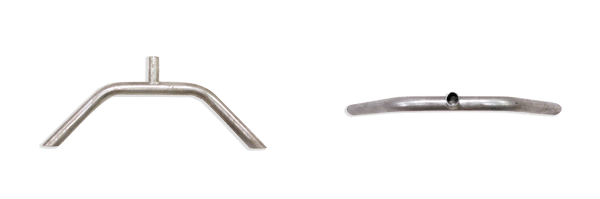

Traditional Bridge Base

The bridge base has been the most popular base style since steel barriers were invented. Bridge bases provide the best resistance to “push” by crowds at events such as parades.

The bridge base has been the most popular base style since steel barriers were invented. Bridge bases provide the best resistance to “push” by crowds at events such as parades.

Bridge bases are designed so that each individual barrier has one large base (a little over 26 inches wide) and one small base (19.5 inches wide). This allows all four points of the base to “dig in” and remain in constant contact with the ground, providing maximum stability on uneven surfaces. Bridge bases also accommodate the placement of barriers in both straight lines, and at various angles.

Flat Base

The flat base is becoming increasingly popular and is particularly ideal when barriers are used as portable pedestrian railings in situations when crowds will be walking parallel to barriers. Barricades with flat bases are used by the New York City Department of Transportation to divert pedestrians around construction sites.

Flat bases for the male and female ends of a barrier are identical in length (23.5” wide), but the placement of the bolt hole is higher on the male end. Rubber inserts for flat bases were introduced in 1998, and most suppliers have now made this feature standard on flat bases. With rubber inserts to protect flooring, flat bases can be used indoors. Rubber inserts are most effective when they are wider on the bottom than on the top.

Most high-quality flat bases now feature beveled corners to eliminate any sharp edges which could potentially cut anyone coming in contact with the base.

Flat bases also feature holes for optional semi-permanent anchoring in outdoor locations.

“U” Base

The U Base is a more recent design similar to the traditional bridge base. Originally utilized by France’s Interior Department, the U base provides excellent four-point stability. U bases are about 22 inches in width on the male end; 17 inches on the female end. The U base also offers the added benefit of rubber stoppers, which reduce sliding and result in damage-free indoor use.

Wheel Base

Wheelbases can be used on both the male and female ends of a barrier, making the barrier easier to move. Each wheelbase consists of two wheels, with a nearly 25-inch width span. When a wheelbase is attached to the male end of a barrier, any other type of base can be used at the other end. The wheelbase is ideal for areas where constant lifting or moving occurs (such as barriers used in parking lots). There are different quality levels of wheelbases, so the size and strength of the wheels and bearings should be considered, especially when a barrier with wheelbases will be used repeatedly.

Inserts

Inserts (with a rubber tip) are available for use as an alternative to a base on the female end of a barrier. Inserts allow barriers to be placed at angles (particularly when flat bases are utilized), keeping the barrier in constant contact with the ground. Inserts are standard on the female ends of 1-meter barriers, and they are not recommended for the longer 2.5-meter barriers.

A Proper Fit?

The base styles discussed above will result in a proper fit for almost all existing styles of barriers. However, there are some discontinued frame variations which may not accommodate the standard base styles. In such rare instances, workable replacement bases are available from most long-standing companies serving the crowd control barrier market

Conclusion

The specification of steel barricades with bolt-on bases is far more cost-efficient than barricades with welded on bases. With interchangeable replacement bases, barricades with damaged bases can be easily and inexpensively put back to work. There are four popular base styles, each offering advantages which have historically been dependent upon the specific use of the barrier or the preference of the entity using the barrier. Most reputable suppliers of steel crowd control barricades can quickly identify and provide the ideal base style which meets their customers’ needs.